The solid foundation for gantry crane is safety base of gantry crane operation. Gantry crane girder design span and arm length design gantry crane wheel track crane span size and electric control etc.

Foundation for gantry crane rail.

. These hoists come with casters but the trolley and chain hoist must be purchased separately. EWEB gantry crane modernization phase I II and III for owner. The power supply can be cable reels or slip line for energy efficiency and reduced operating costs.

With a wealth of experience Gantrail have developed specific checks that can be applied to designs which take account of these rules. Avista Cabinet Gorge Dam gantry crane phase I for owner. Infrastructure Design Challenges Solutions.

Am new to concrete designing this is the first time i will be involved in any of RC related design. Gantry cranes are usually considered when there is a reason not to incorporate an overhead runway system. It is the knowledge and wealth of experience that has been collected during that time that ensures we have the capability to assist you in the design of your crane rail system.

Dognqi gantry crane - Custom gantry crane design with crane span of 36 m. The RC Beam will in-turn support the Rails for the Gantry Crane 8 Ton and 10 Ton. 1 According to the lifting weight install a 3kW electric hoist on the top of the small gantry crane.

The horizontal forces act at the rail level. The design of a gantry crane girder therefore involves the selection of a suitable and workable steel model and section to satisfy the machine crane requirements loading equipment etc without leading to any structural or service failure. Around 2500 for a non-adjusting height crane and would have an equivalent rating to the one being designed.

Especially with automated cranes the tolerances of the rail and the supporting foundations are critical to maximizing efficiency and reducing operational downtimes. Could any1 provide guidelines advice on designing RC Footing Foundation supporting a RC Beam every 6m. Small cranes may consist of an integrated double beam unit.

Priest Rapids 390T gantry crane for contractor. Basic A frame gantry hoist LK Goodwin 2012. RTG Rubber Tired Gantry Crane ASC Automated Stacking Crane SC Automated Shuttle Carrier Acronyms 5.

July 13th 2017 - The track design of gantry cranes is key to the successful operation of the cranes whether they are manually operated RMGC or driverless ASC. Scope Phases 1-5 6 200 Acres 81 Hectares Throughput 16 M TEU. In the following the 5Ton gantry crane.

Poor service life and complete system failures on. Could any1 provide guidelines advice on designing RC Footing Foundation supporting a. Hungry Horse phase I 5 cranes for owner.

This paper aimed to optimize the gantry crane scheduling in the container sea-rail intermodal transport yard. 16DZ2340400 16040501500 15590501700 14DZ2280200 and 14170501500 National Natural Science Foundation of. Concrete beam design for Gantry Cranes.

Gantry crane rail foundation design 230121 Container ports and steelworks can have many kilometres of the heaviest crane rails which carry the highest wheel loads. There is at present no code of practice design guide or specification for the complete design of crane gantries. Types of custom gantry crane designs are for you to save time energy and money.

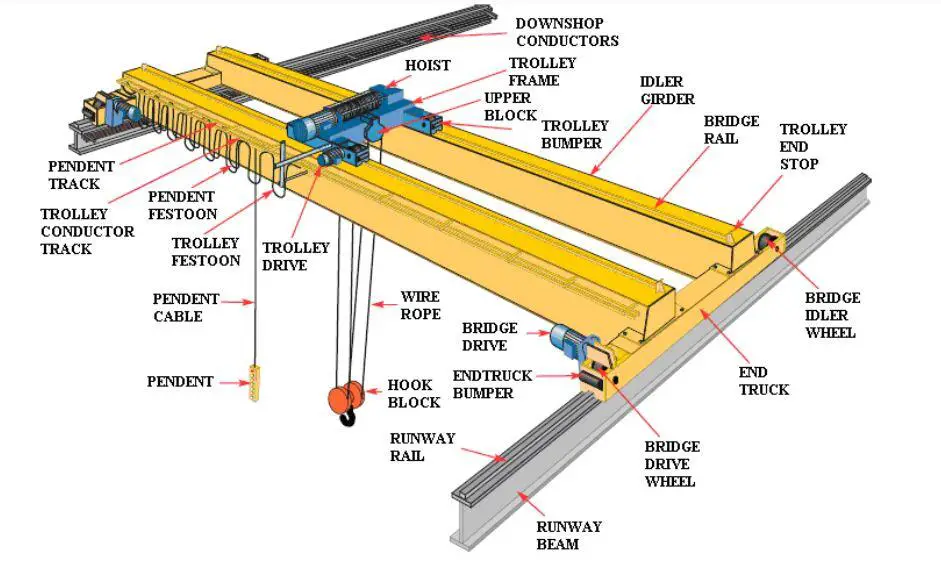

In order to facilitate the sleeper plate in place according to the designed position and facilitate the loading and unloading the electric hoist is installed on a horizontal traveling device. A gantry crane is a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track or rail system. Bonneville Powerhouse intake gantry crane for contractor.

Large cranes consist of a double truss unit. 112 shows the types of beam sections used for gantry girder. Gantry System Articulation Regardless of whether a side shift mechanism is required in the cranes gantry system it is necessary to articulate the trucks and equalizers of the cranes gantry system to avoid significant noise and wear problems.

The 5 factors affect gantry crane design s ie. Were possible these follow national and international rules but they also fill the gap where there is no guidance. Crane Rail Foundation European Rail Section AS 86.

These beams are subjected to vertical and horizontal loads due to dead load of the crane the hook load and dynamic loads. Portal Gantry Foundations. Portal Gantry Foundations like MS3 MS4 Motorway sign Foundations can be fixed using the traditional Concrete Pilling method however industry experts have for quite some time preferred to utilize ScrewFasts Helical Pilling method due to massive savings in cost manpower materials and time combined with the.

We design supply and install a variety of crane rail fixing solutions to suit the type of crane and the underlying foundation either for piled foundation un-piled concrete slab or a ballasted track design. The crane is suitable for yard stacking of containers with 3-4 layers and 6 rows wide. Designers may make reference to a number of sources of information CISC AISC AISE etc which define design criteria.

As a crane moves along a curved path the systems of wheels and. May 30 2013 241 pm. Below is an example of a basic portable gantry hoist design.

The gantry girder is designed on the assumption that either of the horizontal forces transverse to the rails or along the rails act the same time as the vertical loads including the impact load. It is designed with large capacity large span and great height to increase your yard capacity with wider and higher stack possibilities. Narrower rail head through the curve.

Fort Randall bridge cranes rehabre-rate for contractor. One-stop shop offer Gantrex solutions involve the latest technology in crane and specialty rail track component and services including. Design of the railway entering directly into the sea-rail intermodal transport yard avoids the secondary transportation.

Rail Mounted Gantry Crane. Ad Shop A Wide Selection Of Material Handling Equipment To Easily Move Lift More. Rail System Design Rail System Design Gantrail has been designing manufacturing supplying and installing crane rail systems for over 50 years.

There are very detailed design rules for cranes and for the structures on which the rail is mounted. No matter what condition it is there should be foundation under the gantry crane rail to make sure the ground can bearing the gantry cane and wheel Max. Tremendous advances have been made in the mounting of rails for overhead crane systems.

Normally for medium-duty say 25 to 30 t capacity cranes standard universal rolled I-beams are used. Unfortunately these technologies have not been widely applied to rail systems fixed on concrete foundations.

Gantry Crane Rail Fastened To Concrete Foundation With Anchor Bolts Stock Photo Image Of Metal Connection 204155406

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Adjustable Soleplates Gantry Rail

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Crane Rail Refurbishment Maintenance Worldwide Gantry Rail

0 comments

Post a Comment